Tag: Rohacell

SHAPE CONTINUES TO BE FEATURED SPONSOR TO OBR

SHAPE Machining Ltd continues to be a featured sponsor to Oxford Brookes Racing (OBR) after many years of a very close working relationship. Charles Boileve, Head of Business Development at OBR, stated that: “SHAPE has been an integral part of OBR since 2017, where they have helped us massively by machining our tooling blocks with incredible precision. SHAPE is one

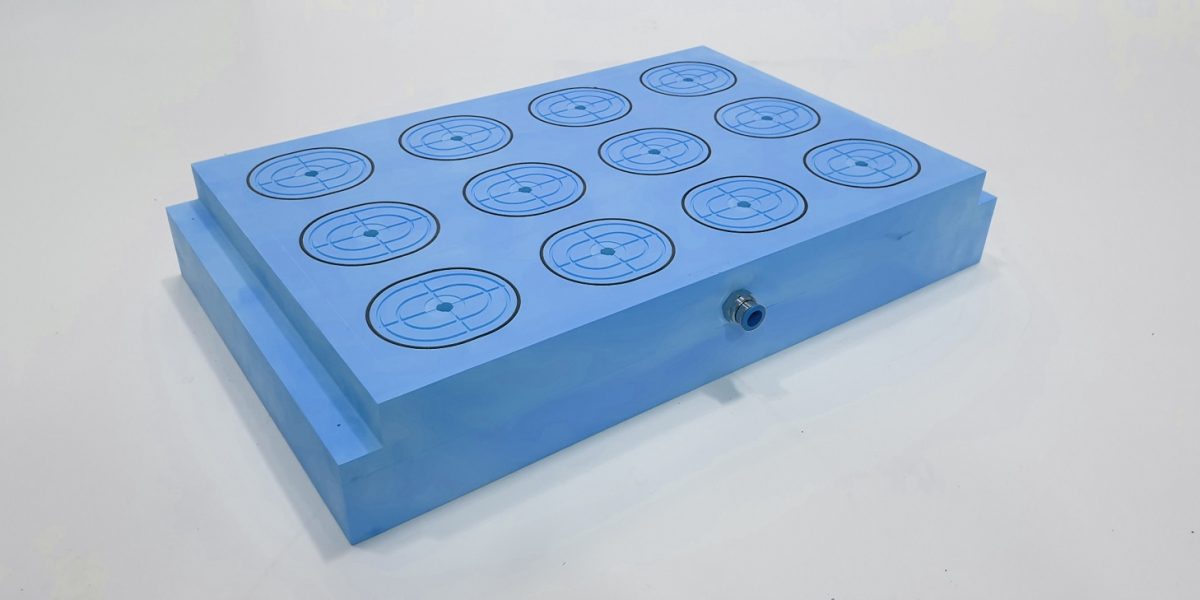

SHAPE Machines Bespoke CNC Jigs To Increase Productivity

Shape are continuing to provide engineering and manufacturing solutions for trimming, bonding and inspection fixtures. This particular fixture was designed and manufactured by Shape and will be used to machine Rohacell foam parts in-house, eliminating hand finishing and allowing Shape to pass this cost saving onto the customer. Managing Director, Ryan Muller, said “We are really proud of our capability

MACHINING A WIDE VARIETY OF MATERIALS

Shape Machining Ltd machines a wide variety of non-metallic materials for a wide range of customers across all industry sectors. Managing Director, Peter McCool, said “Since the company started, nearly 5 years ago, we have always tried to expand the range of materials we can machine. We machine all types of epoxy tooling block, PU styling board and Rohacell foam.

WELL PACKAGED PATTERNS SHIPPED FROM SHAPE

It’s a busy time of the year for Shape Machining Ltd. But they still insist that any patterns they machine are fully protected prior to shipping to customers. Managing Director, Peter McCool, said “The team at Shape know that our customers value the quality of the patterns we machine. So we take great care to ensure they are well wrapped

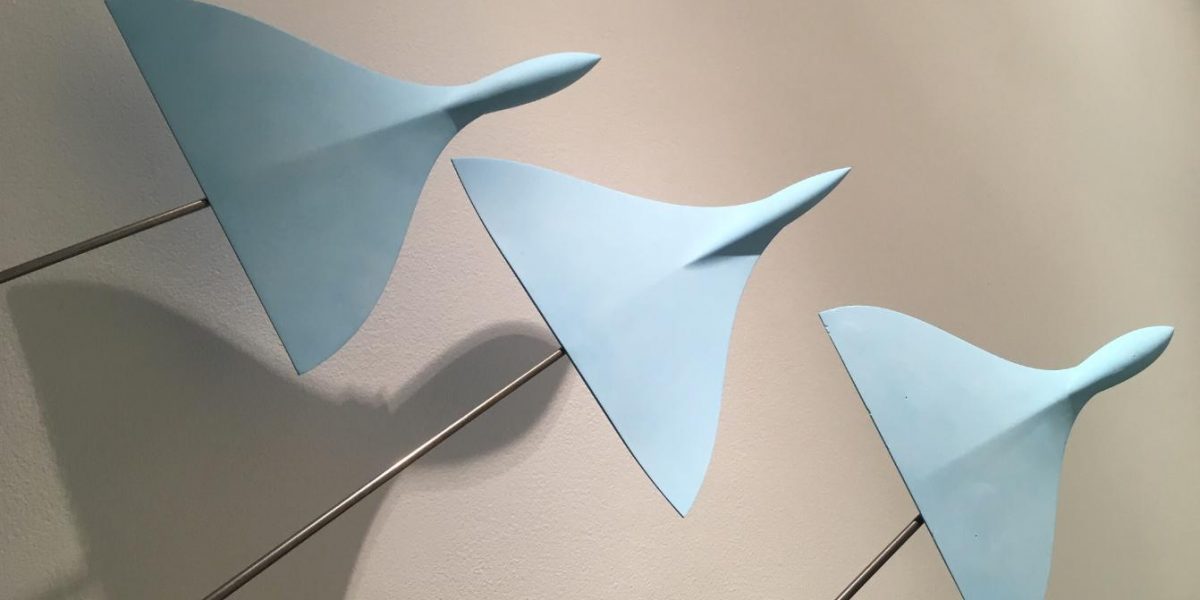

AEROSPACE WORK TAKES OFF AT SHAPE

Aerospace work has been a growth sector for Shape Machining Ltd recently. Managing Director, Peter McCool, said “This has been a good year for Shape and I’m particularly pleased that we are growing our position in the aerospace sector. The fact that we are getting repeat orders from our aerospace customers confirms that our quality and workmanship is of the

COMPLEX ROHACELL MACHINING

Shape Machining Ltd specialises in complex machining to support the composites industry. Machining intricate Rohacell structural foam cores for highly loaded carbon composite parts is one area where Shape has extensive experience. Managing Director, Peter McCool, said “Our customers rely on the quality of the Rohacell parts we machine, so we take great pride in knowing that we are the