Tag: Patterns

SHAPE CONTINUES TO BE FEATURED SPONSOR TO OBR

SHAPE Machining Ltd continues to be a featured sponsor to Oxford Brookes Racing (OBR) after many years of a very close working relationship. Charles Boileve, Head of Business Development at OBR, stated that: “SHAPE has been an integral part of OBR since 2017, where they have helped us massively by machining our tooling blocks with incredible precision. SHAPE is one

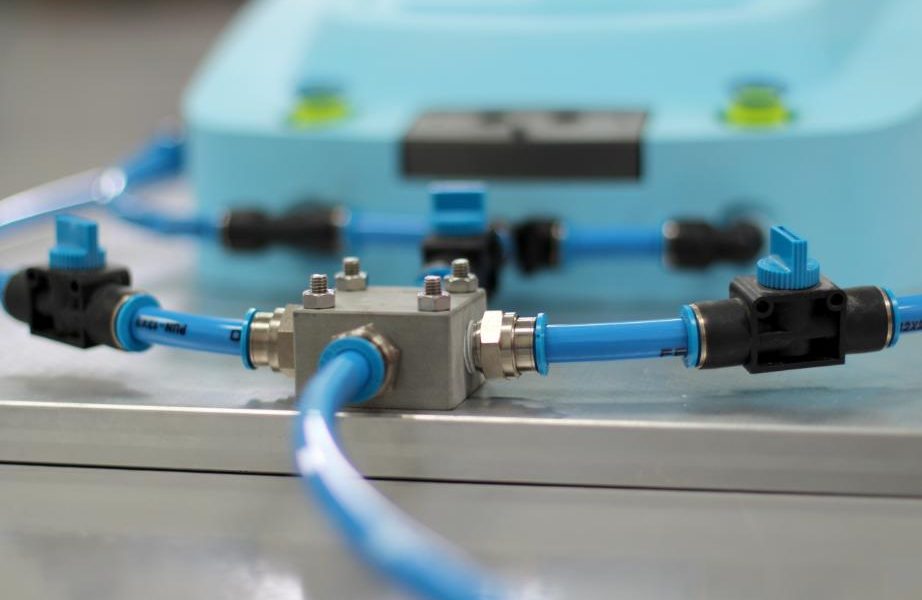

THE FULL ENGINEERING SERVICE

Shape Machining Ltd offers a full engineering service to our automotive and aerospace customers. Shape are continuing to provide engineering and manufacturing solutions for trimming, bonding and inspection fixtures. This particular fixture was designed and manufactured by Shape and will be used to trim CFRP components in house. Managing Director, Peter McCool, said “We are really proud of our capability

WINNING ENGINEERING DEVELOPMENT

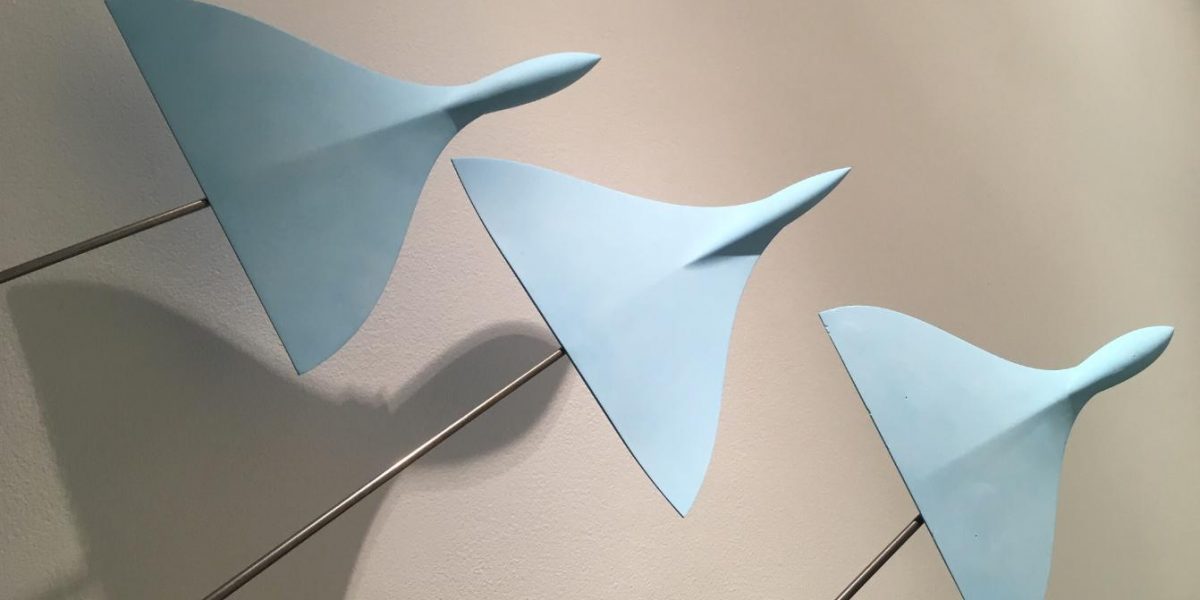

Shape Machining Ltd is proud to be working with top UK Formula Student team Oxford Brookes Racing. Shape provides accurate CNC machined patterns and Rohacell foams to support the manufacture of the carbon composite structures used on their 2019 car that is due to compete at Silverstone on July 19th 2019. Managing Director, Peter McCool, said “We are really proud

OPEN HOUSE EVENT AT SHAPE TO MARK 5th BIRTHDAY

Shape Machining Ltd invites everyone receiving this press release to an Open House Event at our facilities on the 3rd of July. The event will showcase Shape’s advanced manufacturing capabilities and mark our 5th Birthday. Customers, suppliers and friends of SHAPE are all invited to visit on the 3rd of July to view our machines, our facilities, see our capabilities

F1 OPERATIONS EXPERIENCE AT SHAPE

Shape Machining Ltd is pleased to announce that Brian Campbell has joined as Operations Manager. Brian joins Shape from respected Formula One team Williams Grand Prix Engineering, where he spent 29 years, starting as a pattern maker and working his way up through the company to Manufacturing Manager. Ideal experience for his new role at Shape. Managing Director, Peter McCool,

MACHINING A WIDE VARIETY OF MATERIALS

Shape Machining Ltd machines a wide variety of non-metallic materials for a wide range of customers across all industry sectors. Managing Director, Peter McCool, said “Since the company started, nearly 5 years ago, we have always tried to expand the range of materials we can machine. We machine all types of epoxy tooling block, PU styling board and Rohacell foam.

WELL PACKAGED PATTERNS SHIPPED FROM SHAPE

It’s a busy time of the year for Shape Machining Ltd. But they still insist that any patterns they machine are fully protected prior to shipping to customers. Managing Director, Peter McCool, said “The team at Shape know that our customers value the quality of the patterns we machine. So we take great care to ensure they are well wrapped

AEROSPACE WORK TAKES OFF AT SHAPE

Aerospace work has been a growth sector for Shape Machining Ltd recently. Managing Director, Peter McCool, said “This has been a good year for Shape and I’m particularly pleased that we are growing our position in the aerospace sector. The fact that we are getting repeat orders from our aerospace customers confirms that our quality and workmanship is of the

ANOTHER LASER SCANNING INSPECTION ARM ADDED AT SHAPE

Shape Machining Ltd has recently commissioned another Faro laser scanning inspection arm as part of the continuous improvement programme. Managing Director, Peter McCool, said “It has always been important for us to ensure that the quality of the patterns we machine is exemplary. We achieve that by rigorous quality control procedures. Part of our standard process is to fully 3D

PATTERN MACHINING CAPACITY QUADRUPLED AT SHAPE

Shape Machining Ltd has quadrupled the capacity of epoxy pattern machining from the same time last year, as a result of recent expansion. Managing Director, Peter McCool, said “We have had a busy year at Shape and the result is that we have much more pattern machining capacity in place now compared to this time last year.” Shape added 3