News & Press Releases

SHAPE MACHINES NOVEL CARBON MATERIAL

SHAPE MACHINES NOVEL CARBON MATERIAL 17.02.2020 Shape Machining Ltd is machining a greater variety of advanced materials than ever before. As well as patterns and foams, SHAPE is also machining Carbon inserts for the F1 and motorsport industry as well as trimming complex advanced material assemblies. Managing Director, Ryan Muller said “We are primarily focussing our efforts on being the

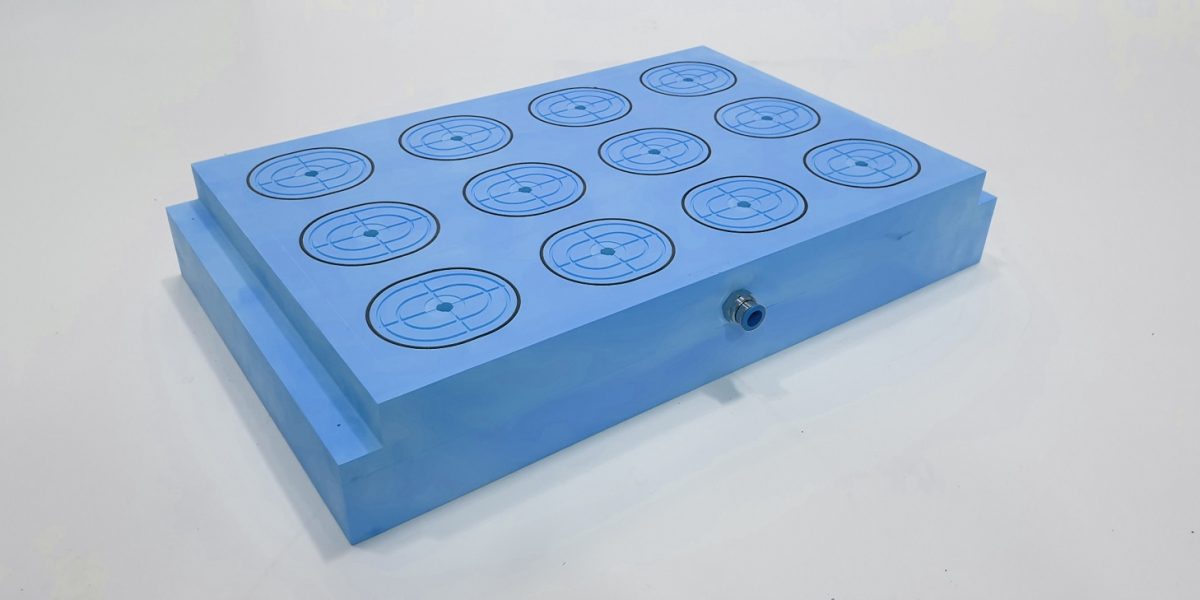

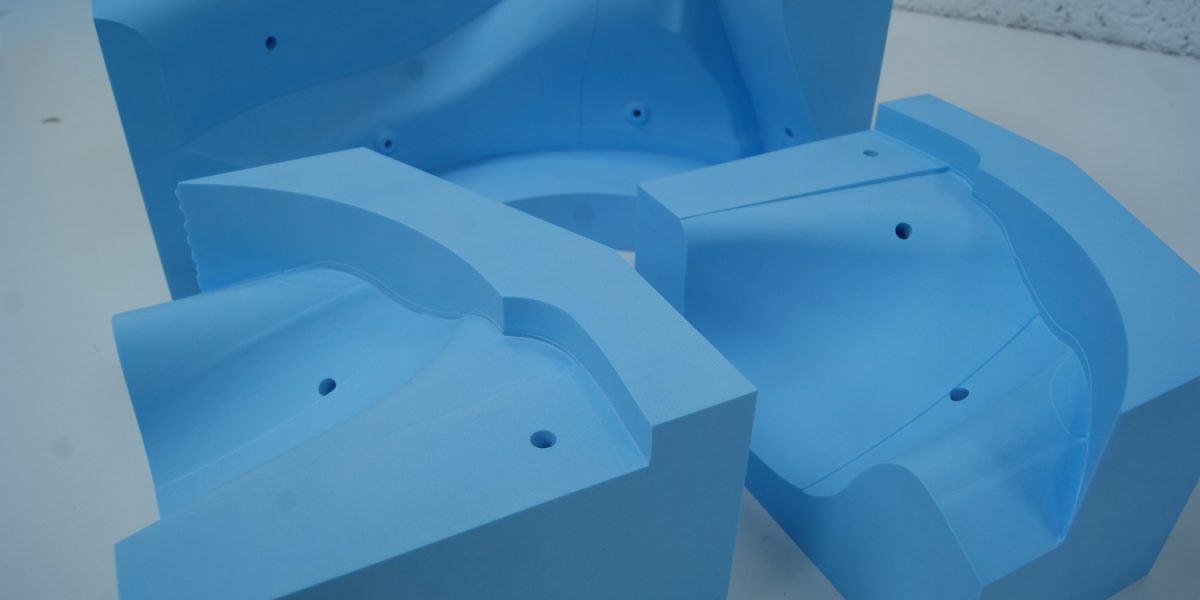

SHAPE Machines Bespoke CNC Jigs To Increase Productivity

Shape are continuing to provide engineering and manufacturing solutions for trimming, bonding and inspection fixtures. This particular fixture was designed and manufactured by Shape and will be used to machine Rohacell foam parts in-house, eliminating hand finishing and allowing Shape to pass this cost saving onto the customer. Managing Director, Ryan Muller, said “We are really proud of our capability

SHAPE adds manufacturing capacity for F1 car build

ADDED MANUFACTURING CAPACITY AT SHAPE MACHINING 23.12.2019 Shape Machining Ltd has increased its workforce by employing additional pattern makers, allowing for reduced lead times and also quicker reactivity to tight deadline RFQ’s. Managing Director, Ryan Muller said “We are absolutely delighted to have a solid skill base as well as a large variety of competency within the business. Having additional

SHAPE Machines Carbon for F1, Motorsport, Aerospace and Automotive

CARBON INSERT MACHINING AND TRIMMING 12.11.19 Shape Machining Ltd is machining high quality Carbon inserts for the Motorsport and Formula 1 industry alongside Carbon trimming for Aerospace and Automotive clients with full FAI reporting and FARO inspection. Alongside the internal capability to design jigs and fixtures in-house, SHAPE has continuously developed methods to machine a variety of advanced materials, including

INNOVATIVE CARBON FIBRE SUSPENSION LINKS

Shape Machining Ltd has designed, manufactured and successfully tested a carbon fibre suspension link for a high-end automotive manufacturer (OEM). The impressive design uses ShapeTex and epoxy thermoset resins technologies to make a part that can be pressed in very short cycle times. The advantage of this technique over a formed aluminium part is a 45% weight saving. Managing Director,

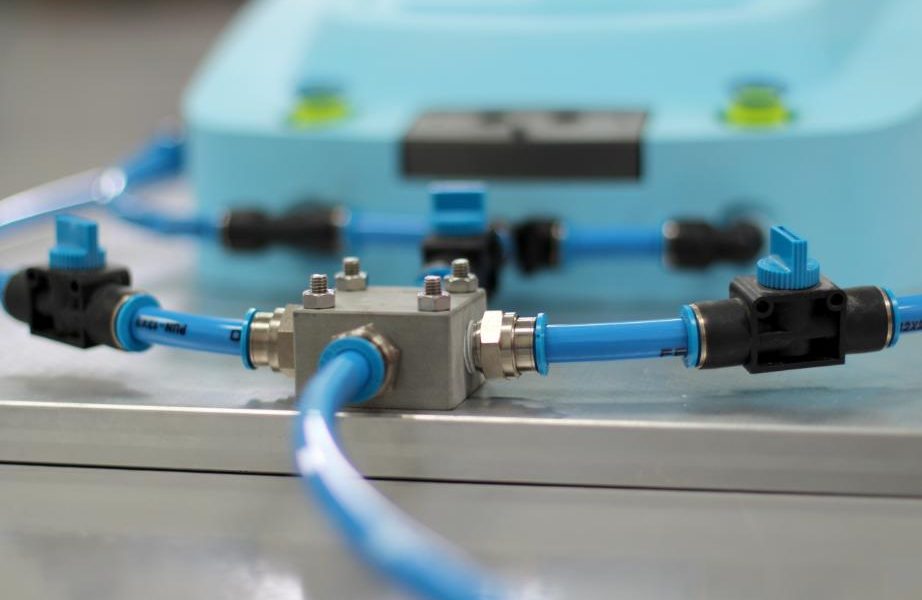

THE FULL ENGINEERING SERVICE

Shape Machining Ltd offers a full engineering service to our automotive and aerospace customers. Shape are continuing to provide engineering and manufacturing solutions for trimming, bonding and inspection fixtures. This particular fixture was designed and manufactured by Shape and will be used to trim CFRP components in house. Managing Director, Peter McCool, said “We are really proud of our capability

WINNING ENGINEERING DEVELOPMENT

Shape Machining Ltd is proud to be working with top UK Formula Student team Oxford Brookes Racing. Shape provides accurate CNC machined patterns and Rohacell foams to support the manufacture of the carbon composite structures used on their 2019 car that is due to compete at Silverstone on July 19th 2019. Managing Director, Peter McCool, said “We are really proud

OPEN HOUSE EVENT AT SHAPE TO MARK 5th BIRTHDAY

Shape Machining Ltd invites everyone receiving this press release to an Open House Event at our facilities on the 3rd of July. The event will showcase Shape’s advanced manufacturing capabilities and mark our 5th Birthday. Customers, suppliers and friends of SHAPE are all invited to visit on the 3rd of July to view our machines, our facilities, see our capabilities

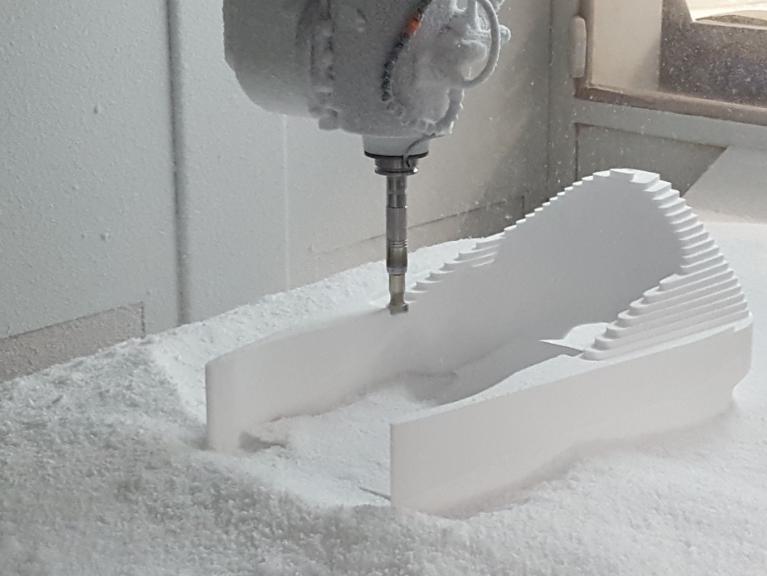

COMPLEX SHAPES MACHINED IN FOAM

Shape Machining Ltd regularly machines complex parts from a variety of technical and industrial foams. Expandable Polystyrene (EPS) and Expanded Polypropylene (EPP) are used in a variety of applications by customers of Shape. Managing Director, Peter McCool, said “sculptured automotive and aerospace seats are regularly machined directly from complex CAD geometry files, supplied by our customers, in a variety of

F1 OPERATIONS EXPERIENCE AT SHAPE

Shape Machining Ltd is pleased to announce that Brian Campbell has joined as Operations Manager. Brian joins Shape from respected Formula One team Williams Grand Prix Engineering, where he spent 29 years, starting as a pattern maker and working his way up through the company to Manufacturing Manager. Ideal experience for his new role at Shape. Managing Director, Peter McCool,