News & Press Releases

Shape Machining is Growing.

Going into 2023 we’re delighted to announce the team is growing. Increased demand along with big plans for 2023 has meant that we needed to bolster our already excellent team. As such we would like to welcome Lewis Wadsley to SHAPE Machining, Lewis has a wealth of knowledge having been in the industry for over 10 years, having taken world

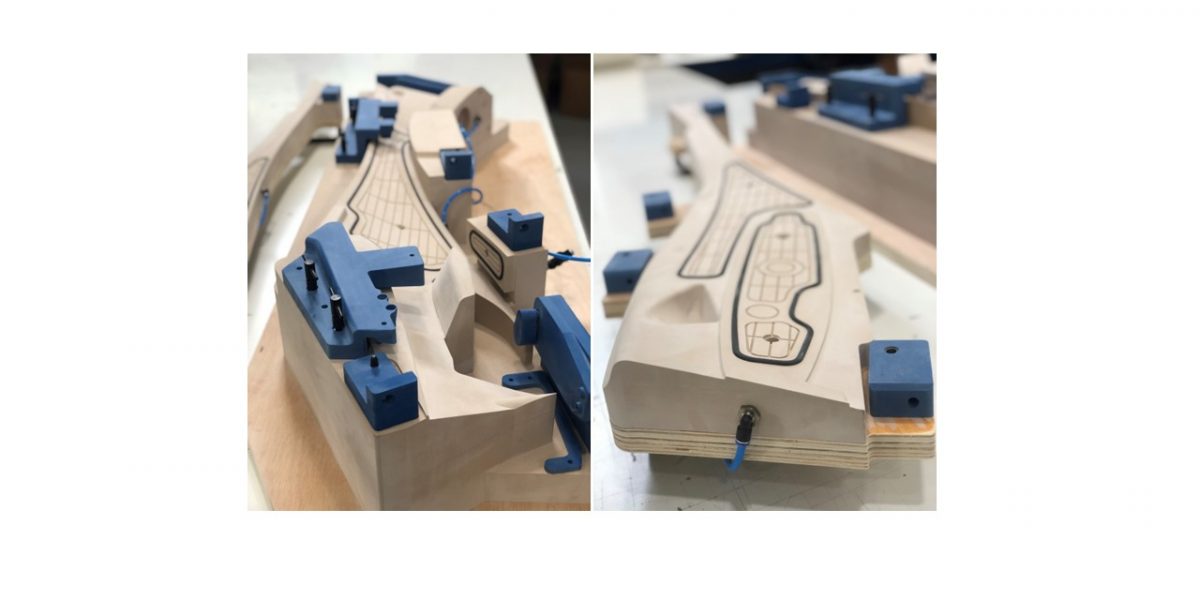

Designed and Manufactured at Shape Machining

A nice example of one of the many projects designed and manufactured inhouse at Shape. This fixture is the final phase of a turnkey project. From component CAD the team at Shape efficiently designed, machined and project managed patterns, composite tooling, and assembly jigs. Adrian Mortlock, Managing Director of Shape Machining Ltd said “With a tight lead-time the engineers and

SUPPORTING THE FUTURE OF ENGINEERING

SHAPE Machining Ltd has been present at the Formula Student UK event once again this year, sponsoring four different teams in different classes. Adrian Mortlock, Managing Director of SHAPE Machining Ltd said “We are very proud of our long-term association with Formula Student, as we firmly believe in the importance of the event in the professional development of its participants.”

Shape machine Rohacell

Synonymous for specialising in the machining of Epoxy, PU and CFRP, Shape also continues to support the composite/motorsport and aerospace industries machining Rohacell products. Managing Director, Adrian Mortlock, said “We have a core customer base we support consistently machining medium to high volume Rohacell components. The programmers at Shape are used to seeing complex Rohacell parts, they have the experience

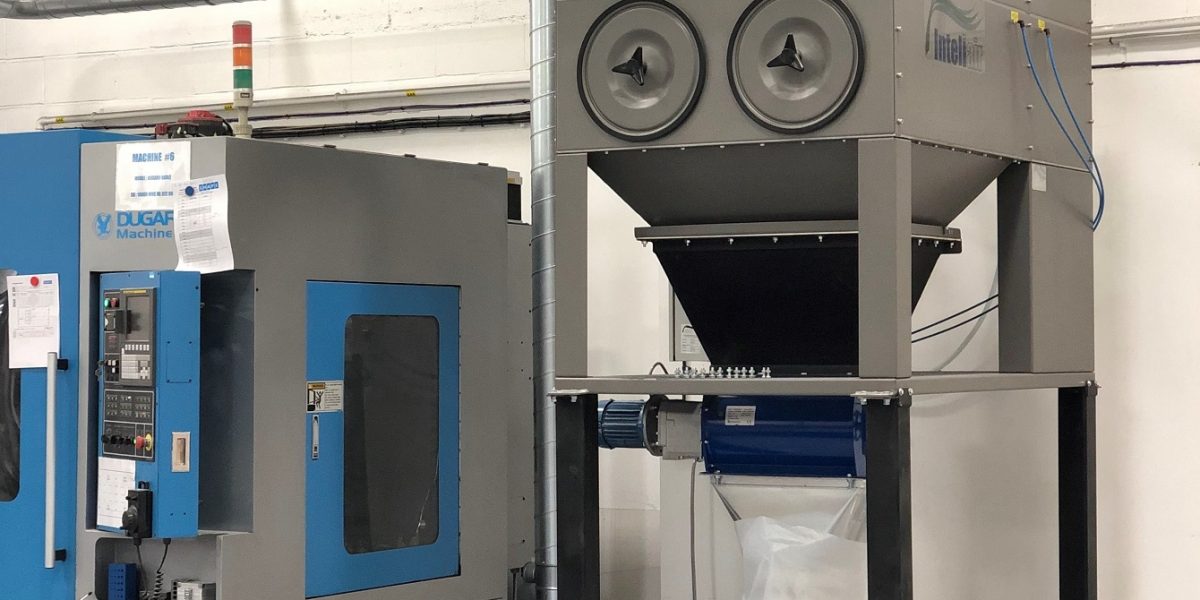

Shape upgrade: new extraction system to support carbon machining.

Shape have installed a state-of-the-art extraction system to ensure the growth of carbon machining is supported by the continual development of infrastructure. Adrian Mortlock, Managing Director of Shape Machining Ltd said “We are always striving to optimise our capabilities and it’s paramount that we do this in a safe and smart environment” Mortlock added “Future proofing is key, the extraction

Upgraded inspection software to meet evolving customer needs

Shape have invested in the latest Polyworks inspection software to allow versatile part validation and tailored inspection reporting. Adrian Mortlock, Managing Director of Shape Machining Ltd said “During the latest F1 build we have noticed a trend in customers requiring patterns, tools and fixturing to be inspected in a variety of different ways. To keep ahead of the curve the

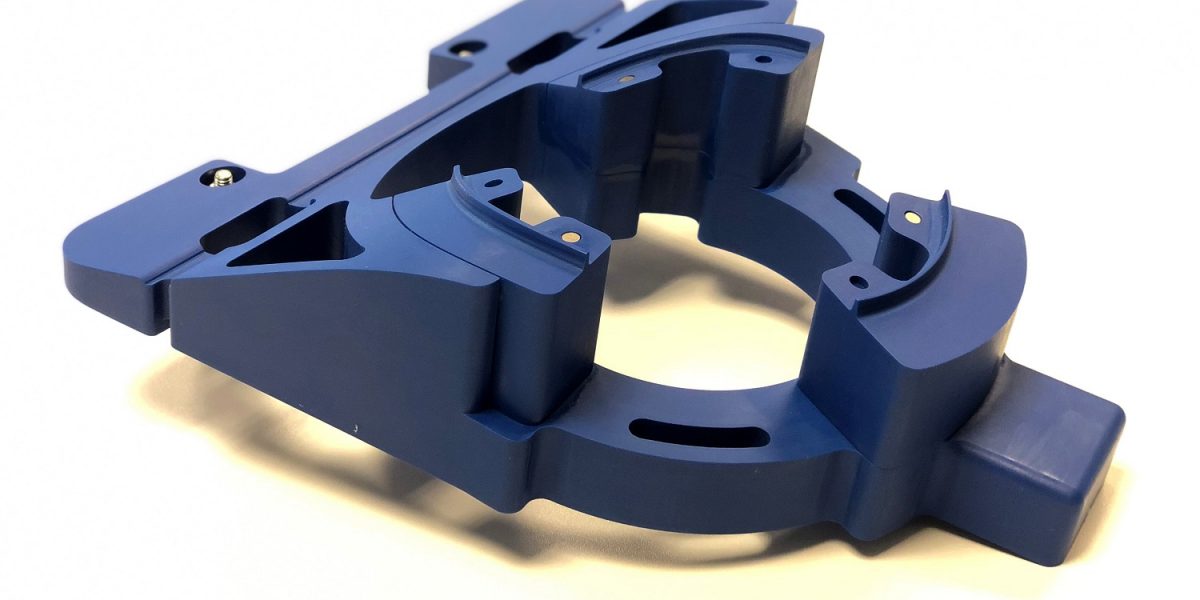

Shape Machine High Density PU

A nice example of a jig designed and manufactured inhouse at Shape. Adrian Mortlock, Managing Director of SHAPE Machining Ltd said “The ability to machine high density PU offers our designers and our customers the capability to engineer robust and intricate details on fixturing that just wouldn’t be viable in lower density board” Mortlock added “Our team ran a series

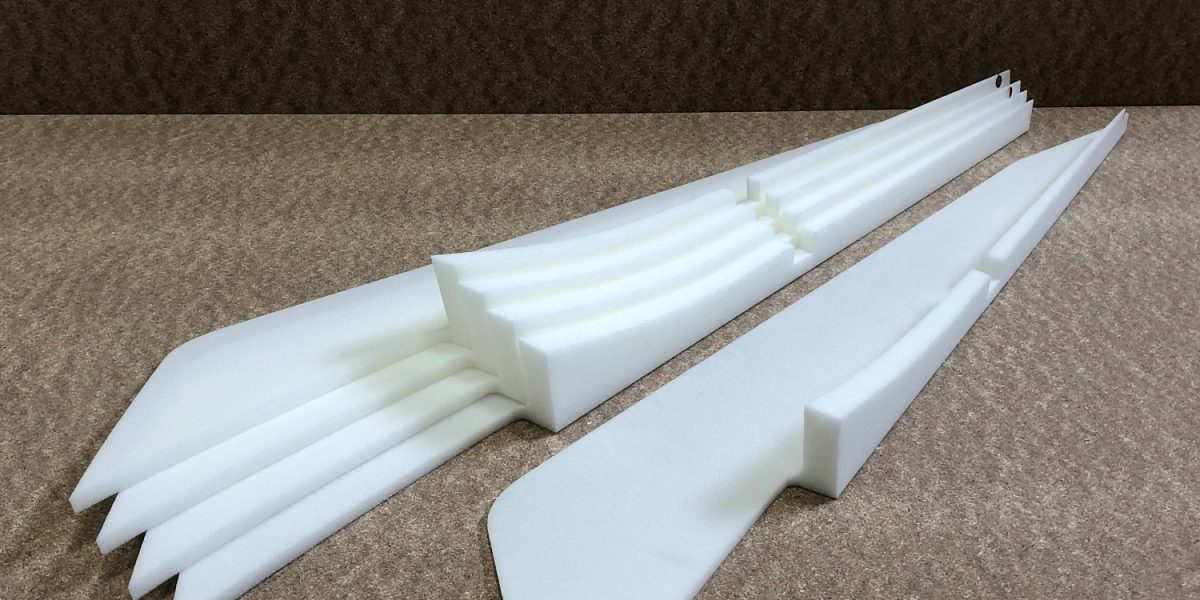

SHAPE – R&D aiding high volume foam machining

Upfront R+D enabled a quick turnaround, high volume packaging solution for one of our aerospace customers. Adrian Mortlock, Managing Director of SHAPE Machining Ltd said, “The engineers and machinists at Shape worked through a number of possible solutions before pairing the correct material with optimum machining parameters to hit the brief. Developing and manufacturing samples allowed our customer to review

Shape Machine Carbon

With demand growing for carbon machining Shape have responded by dedicating a 3-axis CNC machine solely for carbon insert machining. Adrian Mortlock, Managing Director of SHAPE Machining Ltd said “we were noticing a trend, our customers are requiring more carbon machining, and we can now offer a solution for this” Mortlock added “Shape have historically machined a variety of composite

SHAPE at the NEC

SHAPE Machining Ltd are exhibiting at the Advanced Engineering NEC trade show. Come and find a member of the SHAPE team at stand U72 to discuss Epoxy, PU, Foam and Reinforced Plastics projects. SHAPE Machining specialises in machining metallic tools, epoxy tooling block patterns, Rohacell foams and the trimming of carbon fibre parts for the automotive, motorsport and aerospace industry.