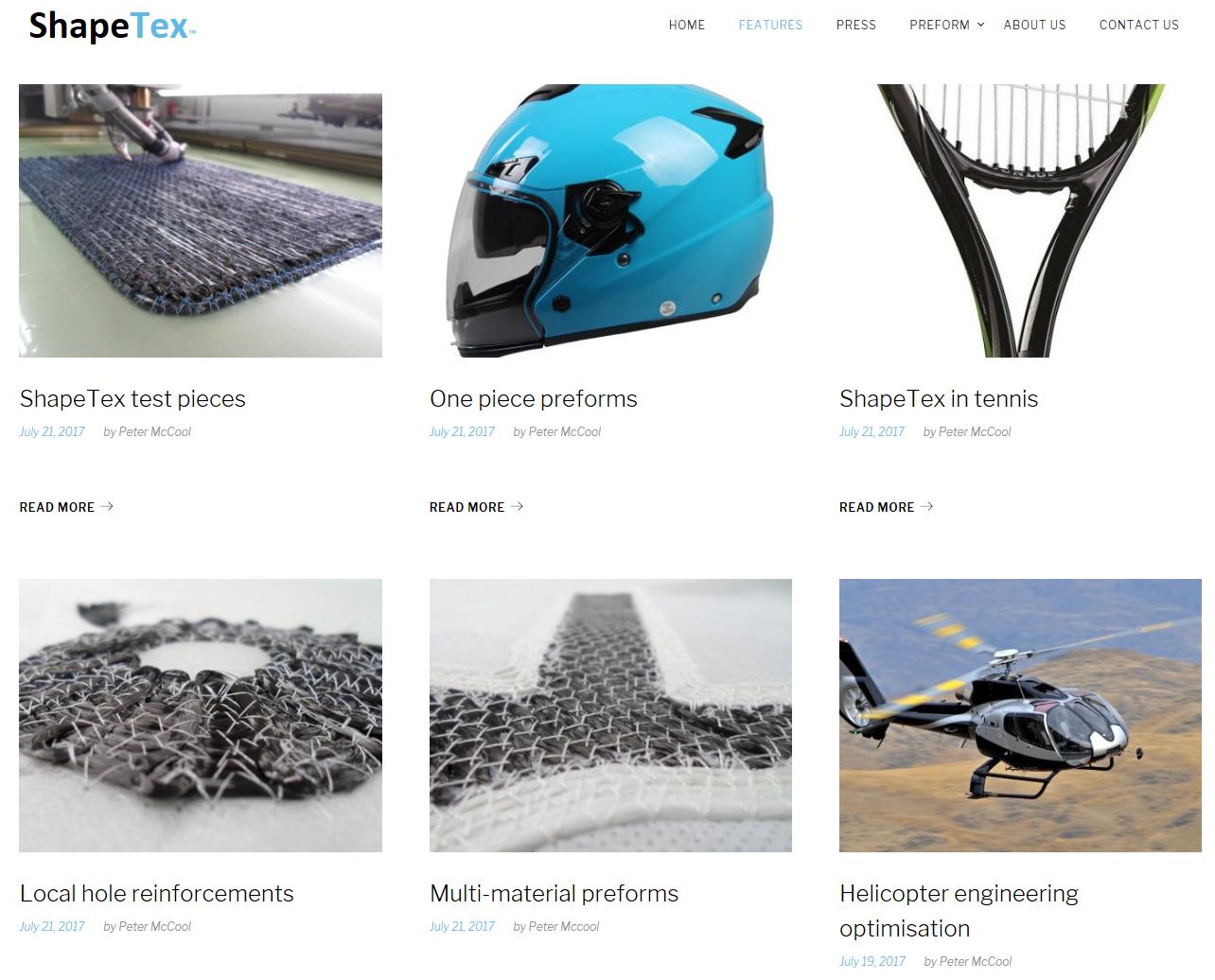

Shape Machining Ltd has today launched a dedicated website for the advanced carbon fibre preform process they have developed under the ShapeTex brand.

www.shapetex.co.uk

The ShapeTex process allows for highly optimised structural preforms to be manufactured with zero waste. Fibres can be accurately laid down in predetermined positions and orientations to ensure the final part has the most optimised properties

Peter McCool, Managing Director, said “We have been developing this technology for a couple of years and the advantages are significant.

A ShapeTex preform is not limited to the warp and weft direction of a fabric preform, and the associated waste, with our process we have unlimited freedom to lay down and orientate the fibres in any direction we want.

We have been working on a number of projects across a range of industries and what we are finding is that our customers are not short of projects where they can see significant efficiency gains from using a ShapeTex preform.”

Shape believes the largest market for ShapeTex is in the design, manufacture and sale of preforms to customers who want to manufacture the end product directly themselves. However, Shape has all the capabilities to design parts, analyse laminates, design tooling, design preforms, machine metallic tooling, manufacture ShapeTex preforms and to press parts all within the one manufacturing site.

Currently many customers use Shape as a one-stop-shop from R&D through to volume manufacture.

McCool continued “We thought most of our customers would come from the aerospace and automotive sectors, but what we are finding is equal take up across all industry sectors with sports and leisure pushing us the most to develop new concepts and get them to market quicker than any other sector”

www.shapetex.co.uk

SHAPE Machining specialises in machining metallic tools, epoxy tooling block patterns, Rohacell foams and the trimming of carbon fibre parts for the automotive, motorsport and aerospace industry.

SHAPE Engineering offers a full range of design, analysis and project management services to support composite part and tool manufacturing projects.

SHAPE Composites supplies thermoset and thermoplastic composite preforms and parts ranging from bespoke autoclave cured carbon parts to larger volumes of hot pressed formed carbon parts.

ShapeTex – Optimised carbon fibre preform design & manufacture

(image from www.shapeTex.co.uk)

Comments are closed.