Shape Machining Ltd has been part of an exciting development with regard to light weight composite parts together with Ultima Forma Ltd.

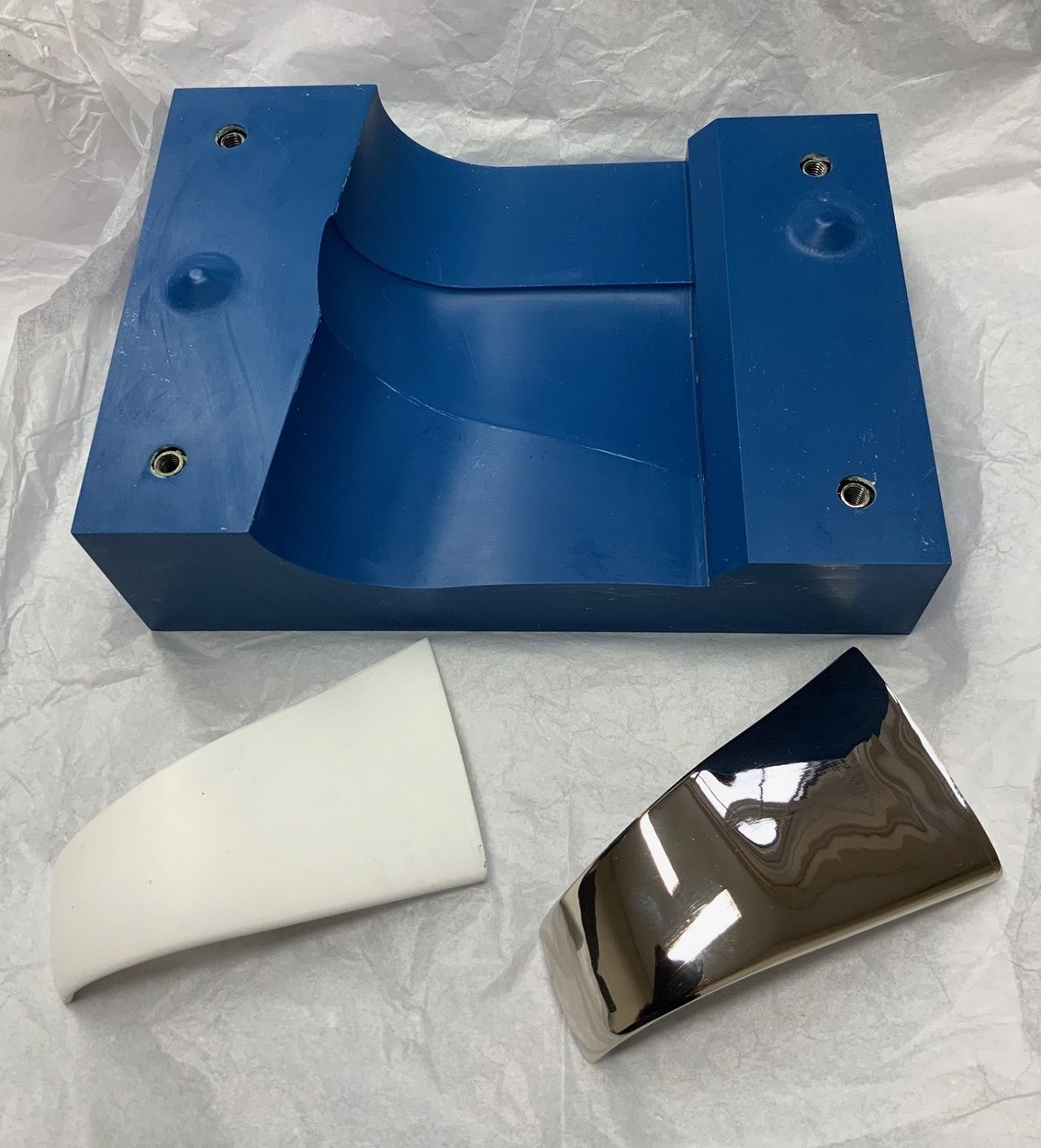

Managing Director, Ryan Muller said “We have seen promising results for electroformed composite parts in terms of performance and mass. Through a similar process to RIM part manufacture, we designed and manufactured PU tooling in order for Ultima Forma to inject the tool and subsequently electroform the resulting part”.

The foam core weighs 14g with 100 microns of electroformed Nickel skin added, producing a high stiffness and damage tolerant composite part weighing 37g.

Muller also added “We have lots of ideas of how to use this technology for composite tooling and parts. We have tried similar processes in the past with other suppliers resulting in limited success – the results we have had from our recent development is very encouraging”.

SHAPE design and manufacture composite tooling and jigs to meet all budgets; from low volume prototyping jigs to full scale series production volume.

For more information on the services offered by Shape, please contact info@shape-group.com.

Image below: Shape designed tooling with resulting part made by Ultima Forma

Comments are closed.