SHAPE Machining Ltd was recently awarded ISO9001 accreditation.

By achieving ISO9001 accreditation SHAPE is demonstrating a continued and constant approach to business and quality improvement.

SHAPE’s customers benefit from the introduction of the ISO Quality Management System (QMS) with a continuously improving level of service. From the moment an enquiry is received to the delivery of a finished pattern or composite part, the process and experience for the customer is of vital importance to SHAPE.

Managing Director, Peter McCool noted “I am extremely pleased with the team for all the hard work that has gone into ensuring that the processes and procedures we have developed for SHAPE have been approved to ISO9001.

Operating within ISO9001 is more than just ensuring that the parts we manufacture are dimensionally correct. It is about ensuring that the whole experience for our customers is a quality experience. We are extremely focused on providing quotes quickly, that all our paperwork is correct, that customers are kept informed of progress and that all parts are manufactured on time.”

Accreditation to the ISO9001 QMS is a prerequisite requirement for supplying into many important industry sectors. SHAPE now hopes to expand more deeply into the automotive, aerospace and industrial sectors having attained this new level of quality approval.

www.shape-machining.co.uk

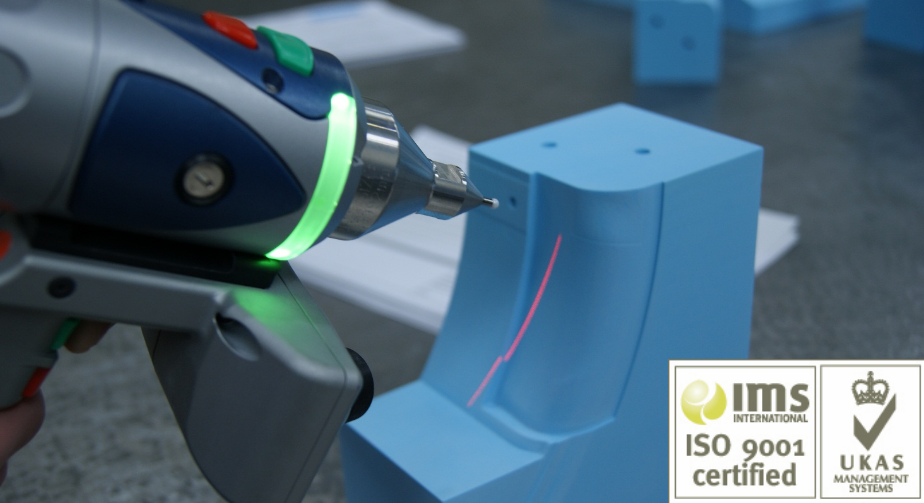

SHAPE Machining specialises in machining epoxy tooling block patterns, Rohacell foams and the trimming of carbon fibre parts for the automotive, motorsport and aerospace industry.

SHAPE Engineering offers a full range of design, analysis and project management services to support composite part and tooling projects

SHAPE Composites supplies thermoset and thermoplastic composite parts ranging from bespoke autoclave cured carbon parts to larger volumes of hot pressed formed carbon parts.

(image of a SHAPE CNC machined pattern being laser scan inspected)

Comments are closed.