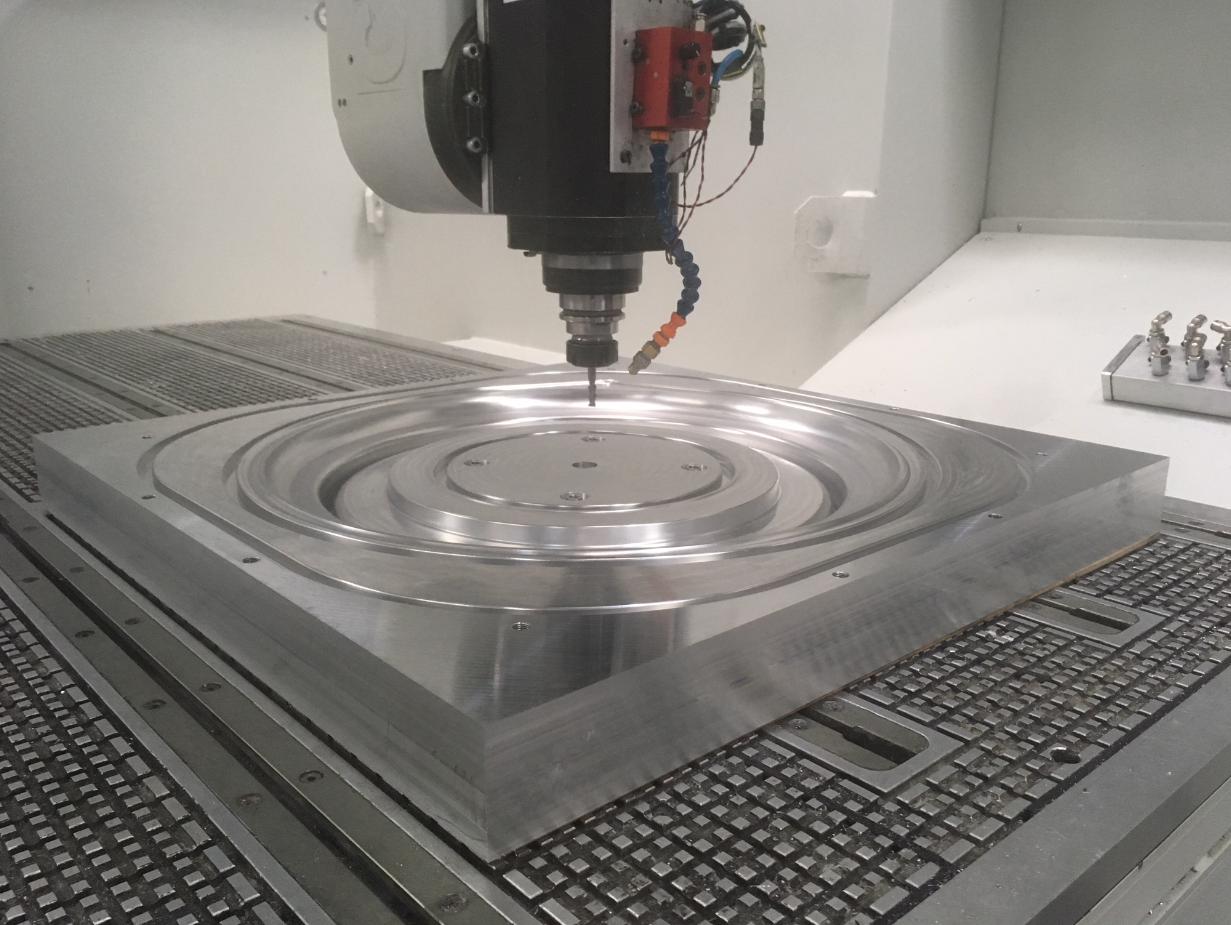

Shape Machining Ltd has large tool machining capacity available to support the composites industry.

Managing Director, Peter McCool, said “After significant recent expansion all our large multi-axis CNC machines are settled-in and machining patterns and metallic tools for our customers.

Our largest machines have 4m beds and are used to machine aluminium tools for RTM and composite press moulding.”

Shape operates from a bespoke 10,000 sq ft facility in Witney, Oxfordshire.

McCool added “We recently machined and polished a set of aluminium tools for a customer who required a highly polished surface because the automotive carbon fibre parts they were making had ‘A-class’ visual surface quality requirements.

This is the type of work we can now offer to all industry sectors as we roll out our plan for being the No.1 in the UK for high quality composite pattern and mould machining.”

Contact quote@shape-group.com for more information.

www.shape-group.com

SHAPE Machining specialises in machining metallic tools, epoxy tooling block patterns, Rohacell foams and the trimming of carbon fibre parts for the automotive, motorsport and aerospace industry.

SHAPE Engineering offers a full range of design, analysis and project management services to support composite part and tool manufacturing projects.

SHAPE Composites supplies thermoset and thermoplastic composite preforms and parts ranging from bespoke autoclave cured carbon parts to larger volumes of hot pressed formed carbon parts.

ShapeTex – Optimised carbon fibre preform design & manufacture

(image of large aluminium tool being machined at Shape)

Comments are closed.