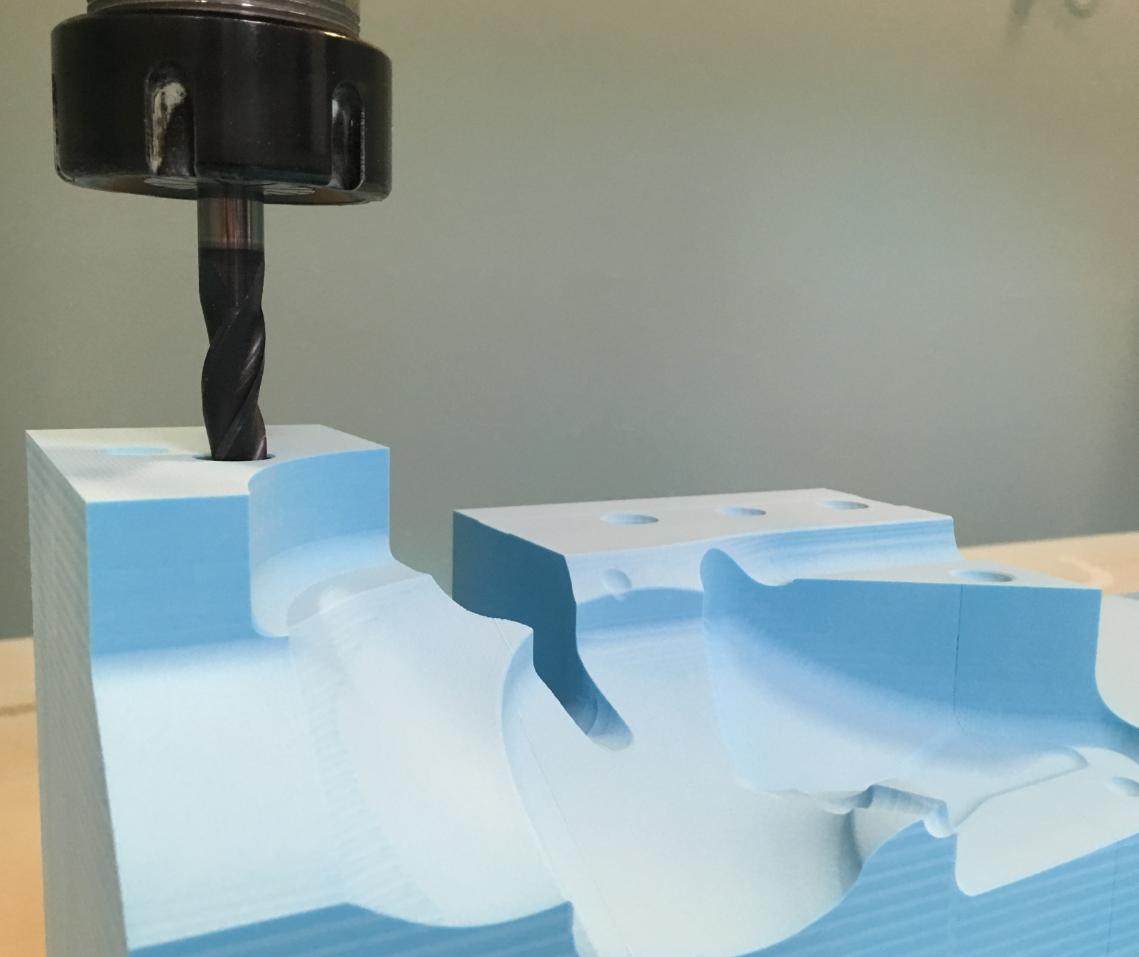

Epoxy tooling block machining capacity has increased at Shape Machining Ltd with the addition of more programming and machining capacity.

Managing Director, Peter McCool, said “I’m delighted that we have more capacity in place for the approaching busy winter period. Our customer base has increased significantly over the last couple of years and this extra capacity enables us to continue to improve the level of support we provide.”

Shape machines epoxy tooling block for a variety of motorsport, automotive and aerospace customers.

All machined patterns are fully inspected using the latest industry leading laser scanning inspection equipment and the whole company works to the ISO9001 quality standard.

McCool added “Our primary goal has always been to support our customers by machining the highest quality patterns. I’m very pleased that this new capacity has been successfully introduced while maintaining the same exacting manufacturing standards we have always had.”

Contact info@shape-group.com or quote@shape-group.com for more information.

www.shape-group.com

SHAPE Machining specialises in machining metallic tools, epoxy tooling block patterns, Rohacell foams and the trimming of carbon fibre parts for the automotive, motorsport and aerospace industry.

SHAPE Engineering offers a full range of design, analysis and project management services to support composite part and tool manufacturing projects.

SHAPE Composites supplies thermoset and thermoplastic composite preforms and parts ranging from bespoke autoclave cured carbon parts to larger volumes of hot pressed formed carbon parts.

ShapeTex – Optimised carbon fibre preform design & manufacture

(image of an epoxy tooling block pattern being machined)

Comments are closed.