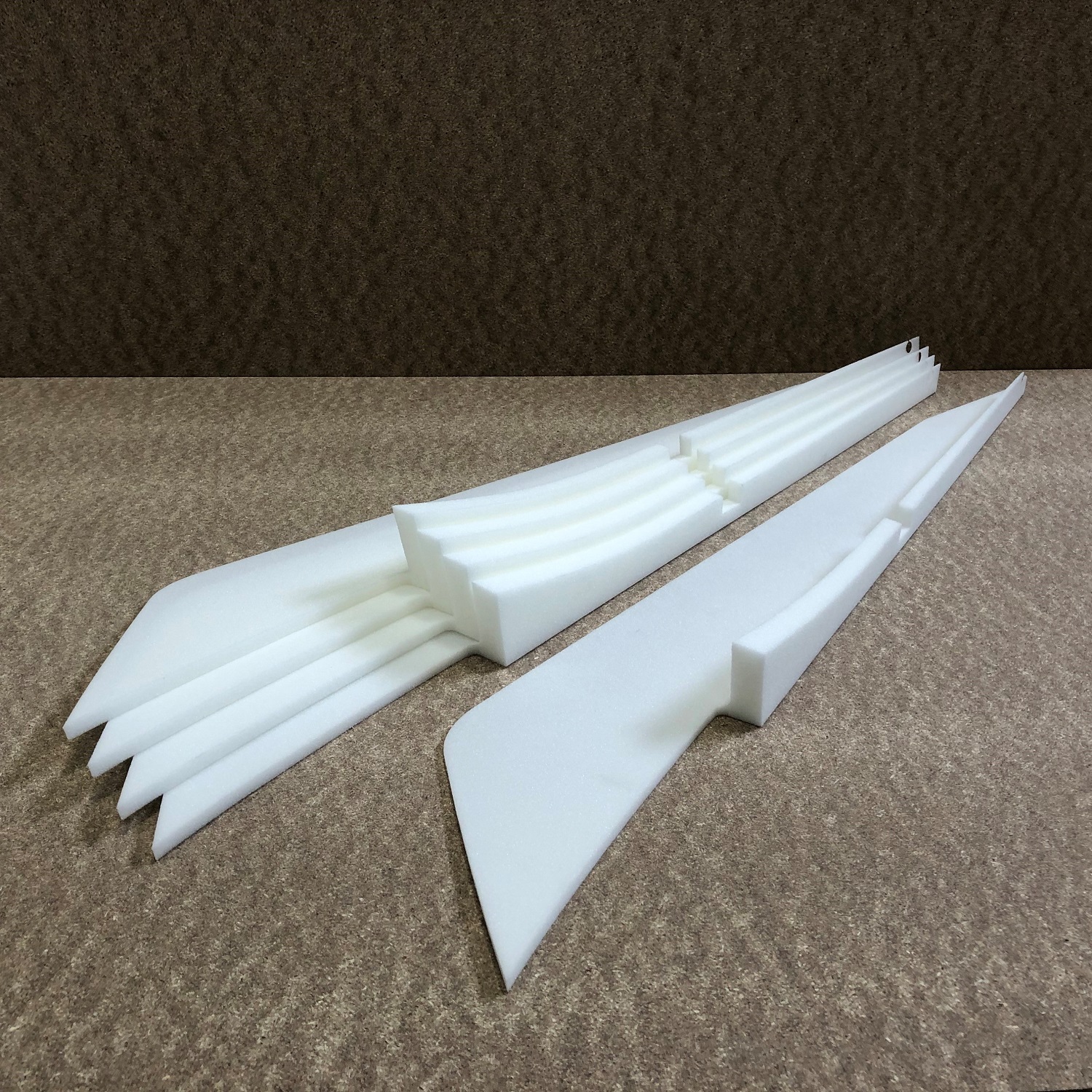

Synonymous for specialising in the machining of Epoxy, PU and CFRP, Shape also continues to support the composite/motorsport and aerospace industries machining Rohacell products.

Managing Director, Adrian Mortlock, said “We have a core customer base we support consistently machining medium to high volume Rohacell components. The programmers at Shape are used to seeing complex Rohacell parts, they have the experience and know how to machine these forms efficiently and accurately.”

Mortlock continued “Our team of engineers recently worked directly with a customer on a high-volume Rohacell production run, designing a series of go-no-go gauges and first article inspection reporting process to ensure the Rohacell parts we produce are right first time. This quality driven approach is applied to every area of the business”

If you have a Rohacell machining project you would like us to review, please contact:

quote@shape-group.com

For more information on what we do, please visit: www.shape-group.com

Comments are closed.