Shape Machining Ltd has delivered a package of metallic press tools for composite component manufacture using the experienced CAD and Engineering Team based in Witney, UK.

Shape design all component parts and tooling using Catia V5, the automotive and aerospace industry standard CAD software suite.

Shape’s Engineering and Composites Manager, Glen Pascoe, said “It is really important to many of our customers that we can take their concepts and lead them through the whole design and production process.

Our level of CAD CAM experience is a significant differentiator between us and our competitors. It is one of our core strengths that we can design complex composite parts and design all the associated tooling and then CNC machine the tools.”

Shape has significant in house multi-axis CNC machining capability for the manufacture of both metallic and non-metallic tooling to the carbon composites industry.

Pascoe added “We are finding that because of our strong engineering background we are becoming the end-to-end supplier of choice for complex tooling covering a wide range of downstream processes.”

www.shape-group.com

SHAPE Machining specialises in machining metallic tools, epoxy tooling block patterns, Rohacell foams and the trimming of carbon fibre parts for the automotive, motorsport and aerospace industry.

SHAPE Engineering offers a full range of design, analysis and project management services to support composite part and tool manufacturing projects.

SHAPE Composites supplies thermoset and thermoplastic composite preforms and parts ranging from bespoke autoclave cured carbon parts to larger volumes of hot pressed formed carbon parts.

ShapeTex – Optimised carbon fibre preform design & manufacture

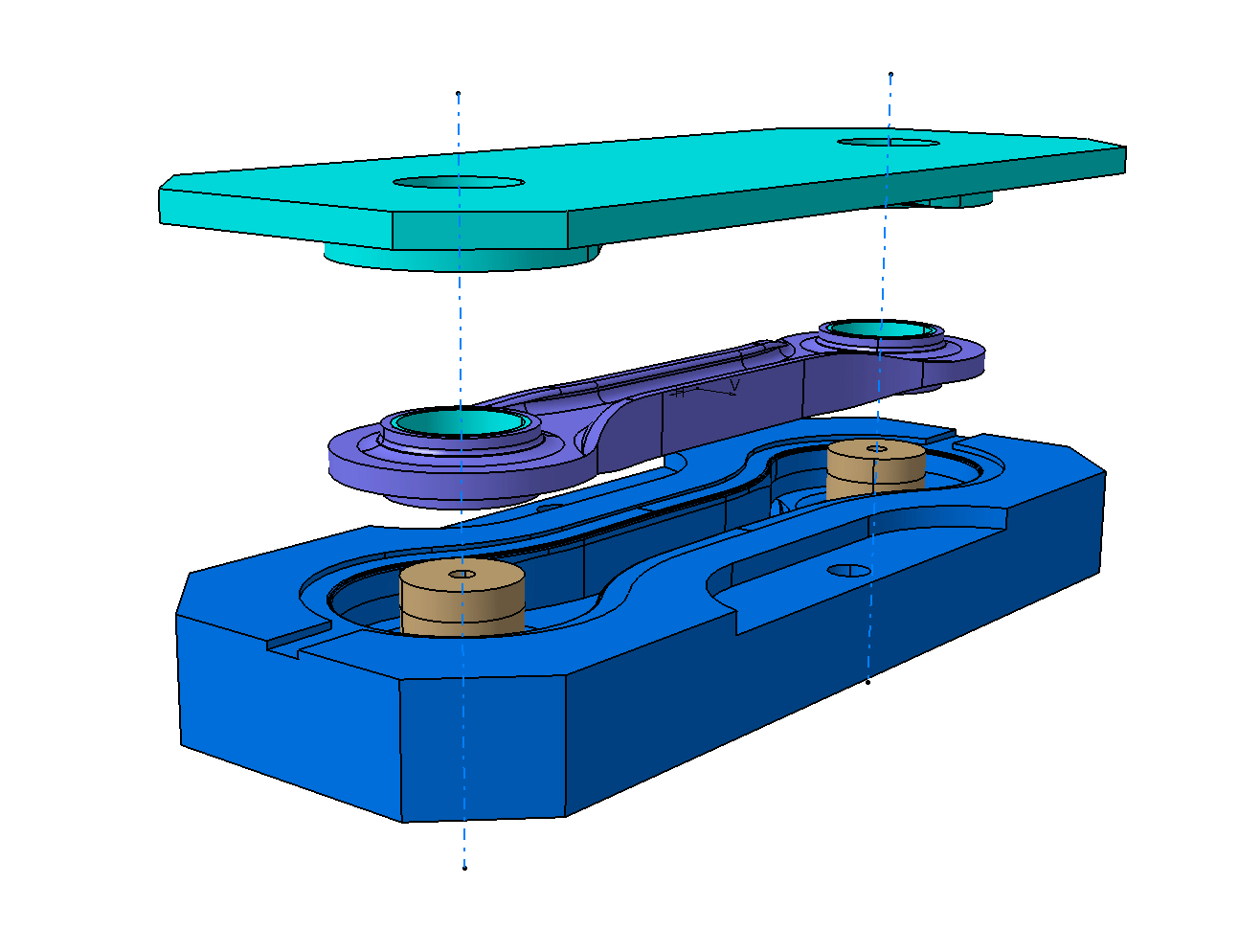

(image of a CAD Tool assembly designed by Shape)

Comments are closed.