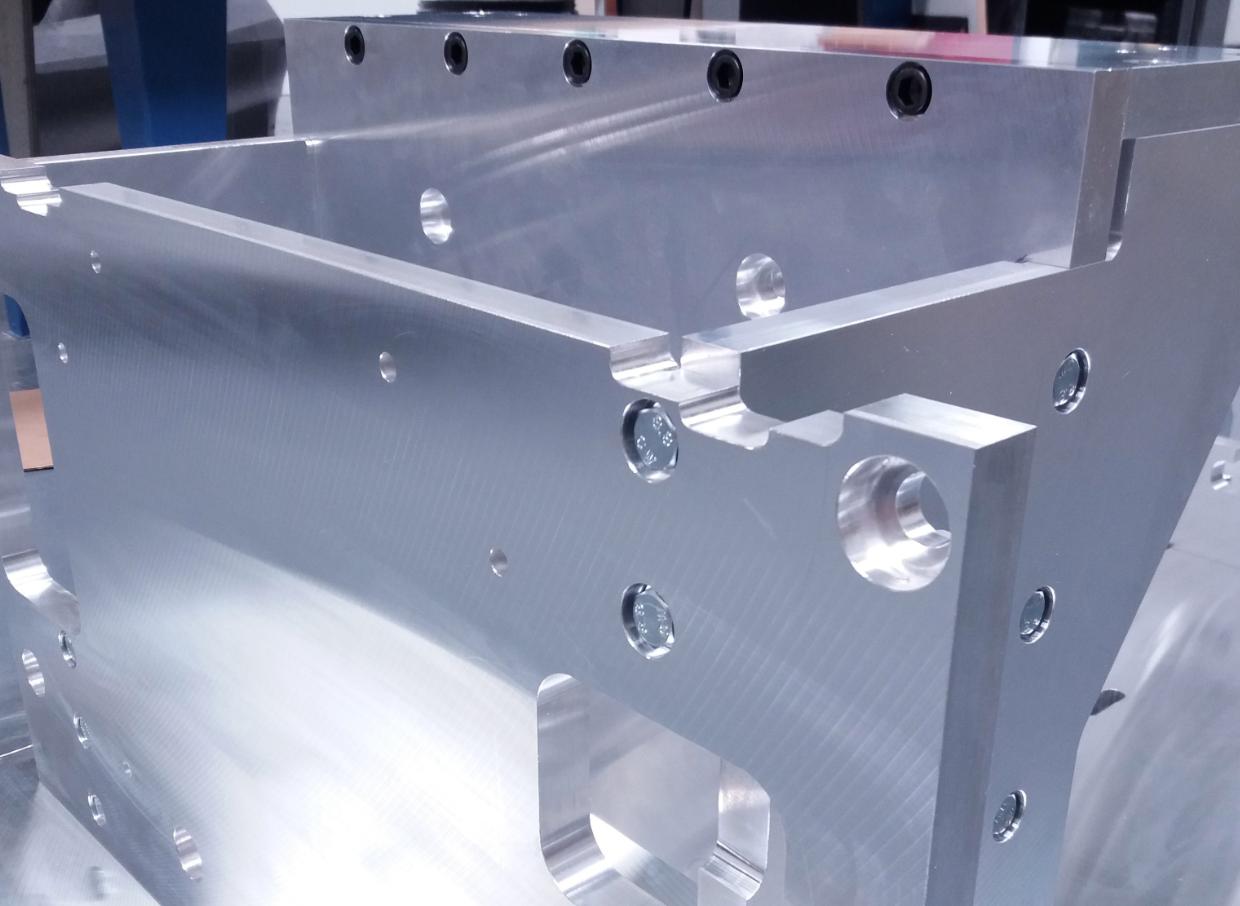

Shape Machining Ltd now supplies aluminium tooling plate fixtures for the automotive, motorsport and aerospace communities.

Managing Director, Peter McCool said “Being able to offer aluminium fixtures has enabled us to support our existing customers with a greater range of capabilities.

We have the in-house capability to design and manufacture a range of jigs and fixtures that includes carbon fibre bonding jigs, CNC machining fixtures, component test rigs, load test rigs, trimming fixtures and inspection fixtures.

Our 5-axis CNC machine with a 3.6m x 2.6m bed can handle most our customers’ requirements for jig plate machining and we use a specialist 3-axis machine for all the smaller parts.”

Shape is already a leading UK supplier of complex 3D tooling (patterns and moulds) to all sectors of the composites industry.

McCool added “It’s very satisfying to design and make complex fixtures like this for our customers”

Contact info@shape-group.com or quote@shape-group.com for more information.

www.shape-group.com

SHAPE Machining specialises in machining metallic tools, epoxy tooling block patterns, Rohacell foams and the trimming of carbon fibre parts for the automotive, motorsport and aerospace industry.

SHAPE Engineering offers a full range of design, analysis and project management services to support composite part and tooling projects.

SHAPE Composites supplies ShapeTex thermoset and thermoplastic composite preforms and parts ranging from bespoke autoclave cured carbon parts to larger volumes of hot pressed formed carbon parts.

(image of an aluminium fixture manufactured by Shape)

Comments are closed.