Shape Machining Ltd is continuing to explore and learn how to machine different advanced composite materials based on customer requirements.

Managing Director, Ryan Muller said “As well as our pattern and foam machining capability, we are striving to become the most rounded advanced material machining company. Through working closely with our suppliers, we have added more and more materials to our machining portfolio including Aluminium filled PU blocks, recycled epoxy tooling board and monolithic T1000 Carbon Composite as well as complete sandwich composite structure bonding and machining”.

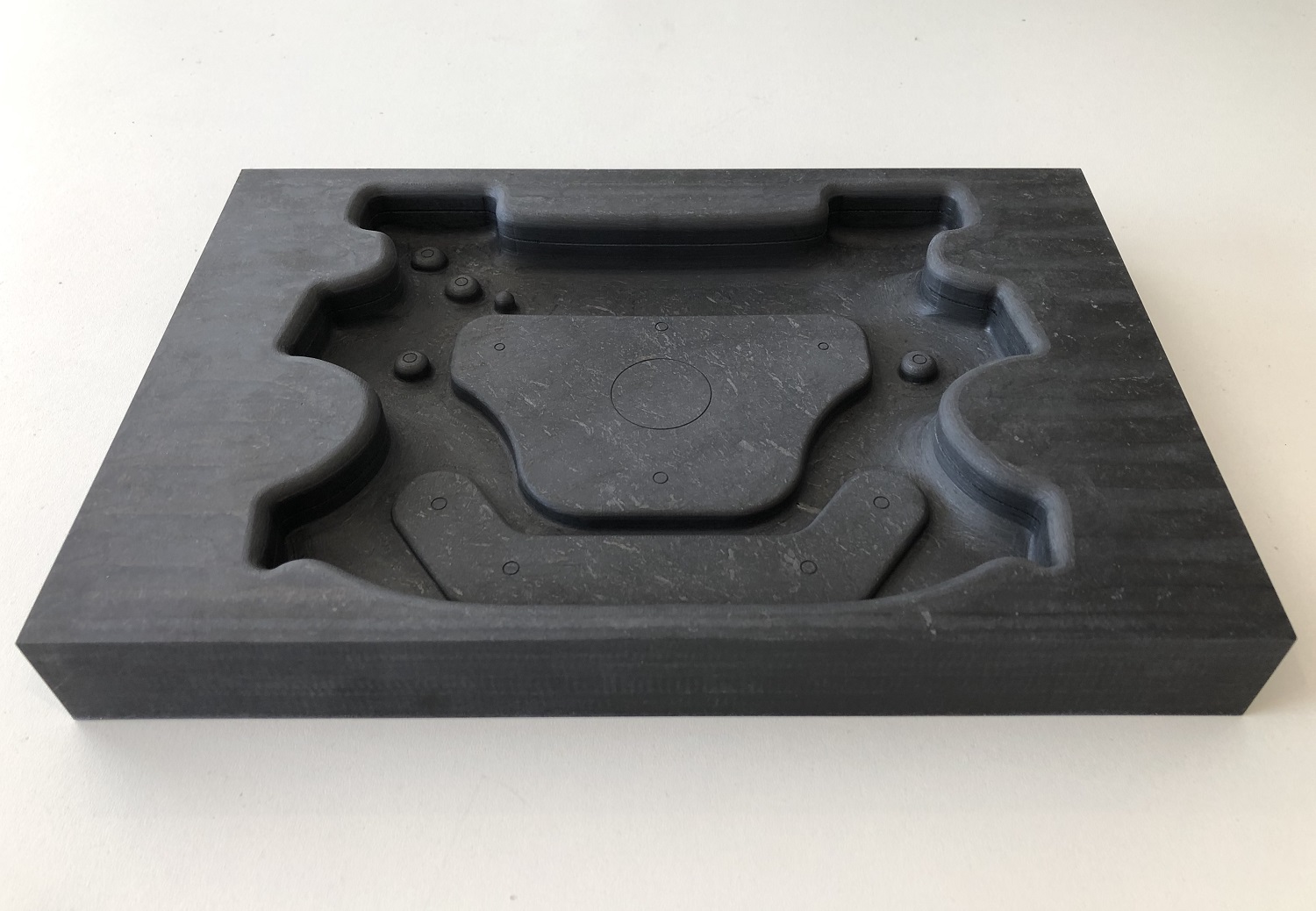

The image shown below is a SHAPE designed motorsport steering wheel tool machined out of “360” Carbon material from the company Carbon Fibre Preforms. This particular material was machined with very low dust and easily hand finished to a high specification. No sealer is required before laminating.

Muller added “We have carried out extensive testing with different types of tool cutters and tool holders to give us the confidence to offer these types of materials to our customers, ensuring we can deliver the highest possible quality”.

For more information on the services offered by Shape, please contact info@shape-group.com.

Image below: Tool machined from CFP’s 360 material (bonded together from flat stock)

Comments are closed.